Picture a bike ride along the seaside. Your T-shirt has a built-in heart rate monitor to track your activity. Floating up from the picturesque water are dozens, maybe hundreds of balloons that feed into a charging station on the beach, where you can recharge your phone to take a photo of the incredible scene. This is the future that Carter Haines, associate research professor at the University of Texas in Dallas, envisions. Haines and his collaborators have figured out a way to turn mechanical energy into electricity with the help of carbon nanotube yarns.

At the heart of the method is a capacitor. The archetypal capacitor is called a parallel-plate electrostatic capacitor, and it consists of a positive and a negative electrode with some dielectric medium in between. This dielectric is a material that stores charge well; the electrodes, by contrast, are conductors through which charge is quickly removed as a current. You can charge a capacitor to a high voltage and then harvest the energy inside it at a later time.

“You take a piece of rubber, coat carbon grease on both sides to get electrodes, and as you stretch and release this rubber you can change the capacitance and get energy out,” Haines said. However, the trouble with electrostatic capacitors is two-fold. First, of course, you have to charge them up with an electronic circuit to start with. Second, a human body, with its high conductivity, probably shouldn’t be near, let alone touching, high voltages.

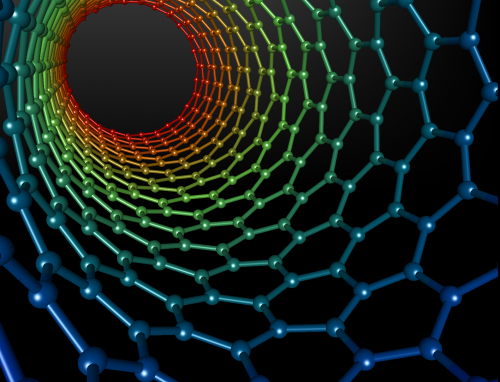

This is the beauty of electrochemical capacitors. Virtually all electrochemical capacitors today have electrodes made of carbon allotropes—different forms of carbon with its atoms interacting in different ways—with high surface areas. Carbon nanotubes are one class of such allotropes. First discovered by Soviet scientists Radushkevich and Lukyanovich in 1952, they are incredibly strong and stiff, with length-to-diameter ratios of up to 100 million. They are grown upright in what is called a forest, then pulled out into fibers and twisted into yarns. “The nanotubes are no longer in the yarn axis, but are following helical paths, just as you’d have with any yarn that you twist,” Haines said. If you continue to twist the yarn under pressure, it will actually form coils; you’ve probably discovered this phenomenon while playing with your shoelaces. With the right amount of tension on the ends of the yarn during the twisting process, you can get neatly packed coils.

The dielectric in an electrochemical capacitor is an electrolyte, a solution of charged ions in a liquid. “Because there’s so much surface area on the surface of the nanotubes, the ions can just come and hang out on the surface,” Haines said. “When we compress the yarn, we’re actually getting rid of surface area.” By pulling one strand (one electrode) and tightening the twist, the ions on it pack closer together, increasing the voltage. Since the ions all have the same sign, they repel each other and are eager to escape. Even a small voltage on the surface area of the nanotubes will collect a large charge—much larger than the charge on their conventional parallel plate counterparts. Thus, electrochemical capacitors have earned the alternate name of “supercapacitors,” and their low voltage means no electrocuted humans.

The most interesting application is the potential for embedding the yarns into clothing. The group has already tracked breathing, which Haines says is just the beginning. “You can measure things like pulse, heart rate and all sorts of things about the way the body is moving just by having different yarns embedded in the textile,” Haines said. The biggest roadblock to a commercial-scale use of energy-harvesting yarns is the production cost of the carbon nanotubes. The search is on for cheaper alternatives that have the same ability to host ions from an electrolyte on an easily changeable surface area.

In the lab and in the fabrics, the electrolyte is some kind of synthetic gel. But it turns out that seawater, with its high salt concentration, also works well. Haines’ collaborators in South Korea did indeed attach a balloon to one end of the yarn and hold the other down to the seabed with a rock. “They can see the voltage coming out of the yarn as the waves are moving the balloon around,” Haines said. Harvesting the mechanical energy of ocean waves has been an open challenge, and one that these yarns may rise to meet—if scientists succeed in finding a way to affordably produce them on the industrial scale.