Imagine if we could turn all the world’s saltwater into drinking water using a simple filter with tiny pores to catch salt particles. Such purification technology, which could save millions of lives, may be possible using materials called nanophase-separated block copolymers (BCPs). Currently, however, production issues prevent BCPs from commercial feasibility. Mingjiang Zhong, assistant professor in Yale’s Department of Chemical & Environmental Engineering, has discovered a way to address this problem.

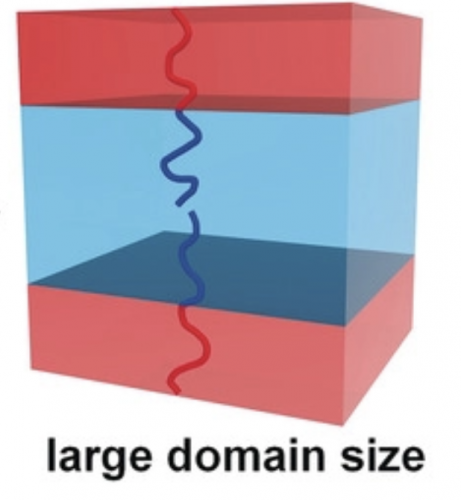

The most common BCP structures are linear diblock copolymers, string-shaped polymers whose two ends repel each other. When multiple strings are put in close proximity, their opposing ends seek to distance themselves from each other, forming tiny gaps around 10 to 200 nanometers. The issue comes when a separation under 10 nanometers—a size necessary for applications ranging from desalination to increasingly small computer chips—is desired.

“Once the polymer chain gets smaller and smaller, the immiscibility [repulsion of the two ends of the BCPs] is decreased,” said Zhong of current BCP technology, which cannot achieve such small gaps without expensive materials and processing techniques.

To address this challenge, the scientists developed Janus graft block copolymers (GBCPs), BCPs that link multiple linear diblock copolymers together to form a structure that resembles a bottlebrush. This structure maintains repulsion of the individual BCPs at increasingly small sizes without sacrificing processing- and cost-effectiveness.

Since publishing his research in Angewandte Chemie, Zhong has focused on scaling the technique to ensure large-scale feasibility. He is collaborating with other Yale researchers to apply GBCPs in desalination membranes and microelectronics, with hopes that this new technology will bring exciting developments across many fields.