These days, it’s hard to escape the reality of climate change in daily life. Carbon dioxide is one of the main greenhouse gas drivers of climate change: according to the EPA, 6,558 tons of the gas were emitted in the United States in 2019 alone. But what if there was a way to ‘harness’ this carbon dioxide and instead transform it into usable energy? Enter: carbon capture.

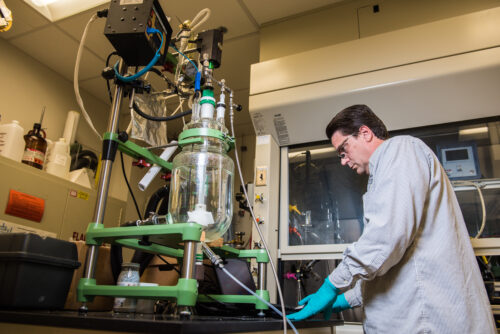

Researchers from the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) recently discovered a new method of integrated carbon capture that converts carbon dioxide into methane, a main component of natural gas. The reactants of this method include waste carbon dioxide, a 2-EEMPA solvent, and renewably sourced hydrogen. While traditional carbon capture methods usually boil the carbon dioxide out (the capture step) before shipping it elsewhere to be converted into methane (the conversion step), this new process simply passes the carbon dioxide over a catalyst and mixes it with hydrogen, all in one chamber, completing the conversion at one site. “Rather than just doing the wasteful regeneration [of carbon dioxide], we’re just doing the conversion at the same time,” Heldebrant said.

And best of all? This method presents the lowest price of carbon capture so far.

The 2-EEMPA solvent used in the method has been in development for fourteen years with corporations such as Florida Corporation, GE Global Research, and University Partners, with twenty-million dollars of Fluor Corporation funding. Unlike traditional solvents, 2-EEMPA has a low water content and thus can more easily dissolve carbon dioxide more easily, while requiring less overall energy to complete the conversion process. Hence, while pPrevious methods required high temperatures to push the equilibrium in favor of the conversion, but 2-EEMPA simply allows the chemicals involved to facilitate the conversion to methane, necessitating only about half of the typically required temperature and pressure.

Because of this ability to reduce the amount of energy used in the conversion of carbon dioxide to methane, using 2-EEMPA in power plants could decrease the price of carbon capture by nineteen percent. “Right now, everybody talks about wanting to do carbon capture, but there is a high cost,” Heldebrant said. Current commercial technology can capture carbon dioxide at $58.30 per metric ton, but this new method costs only $47.10 per metric ton. This method therefore reduces total capital investment by thirty-two percent and the minimum selling price for natural gas by twelve percent.

It’s important to note that while this new process produces methane, which is itself a harmful greenhouse gas, synthetic methane’s carbon neutrality and household and industrial uses still make it an improvement over other forms of methane. Furthermore, Heldebrant’s project was funded in California, where the new low-carbon fuel standard prohibits the use of methane derived from fossil fuels in a few years. This makes Heldebrant’s research even more vital for companies currently relying on producing natural gas. “Ultimately in the long term, we would love to see everything go to renewables, but at least right now, we would much rather see something that’s carbon-neutral as opposed to carbon-positive just pulling the methane out of the ground,” Heldebrant said.

Compared to previous methods, this method’s low price creates financial incentives for carbon capture, but it also creates a potential problem of oversaturation of the methane marketplace once the method becomes large-scale. “If we’re only going to be making methane, you’re going to disrupt the entire methane marketplace, and then that basically means there’s no longer an economic driver to do it,” Heldebrant said.

In the future, PNNL hopes they can find new substances to which they can convert waste carbon dioxide, such as dimethyl ether (a type of diesel additive), cyclic carbonate (a type of electrolyte solvent in batteries), and polymer carbon dioxide. The work to pioneer carbon capture technology at such low costs has been decades in the making, but this new research has finally shown that cheap carbon capture technology is not only feasible, but also has the potential to become a beneficial driver of the economy and environment.